President and Chief Executive Officer Mario Longhi visits the Metallographic Facility inside the U. S. Steel Research and Technology Center in Munhall, Pennsylvania. The addition of the Bruker Advanced X-ray Diffraction System, which analyzes new steels and coatings down to their atomic level, will aid U. S. Steel’s efforts to develop steel products and steel-based solutions and demonstrates our commitment to innovation as part of our efforts to reshape, reposition and transform our company.

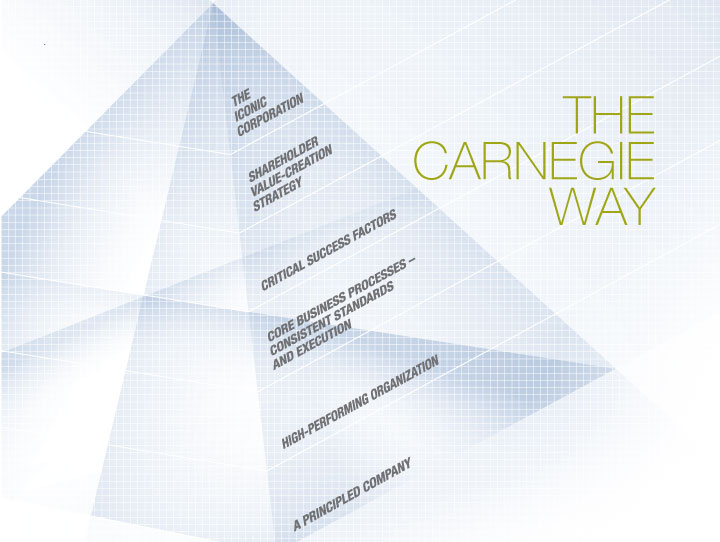

2013 marked the start of the transformation of United States Steel as we execute on our shareholder value creation strategy: earn the right to grow and drive and sustain profitable growth. Through a disciplined approach we now refer to as “The Carnegie Way,” we are working to strengthen our balance sheet, with more intense focus on cash flow, and have launched a series of initiatives that we believe will enable us to add value, get leaner faster, right-size, and improve our performance across our core business process capabilities, including commercial, supply chain, manufacturing, procurement, innovation, and operational and functional support. We are on a mission to define and create a sustainable competitive advantage with a relentless focus on economic profit, our customers, our cost structure and innovation.

Our company has long been considered an icon of American industry, but that status has been challenged as we weathered five consecutive years of losses. We now must do our best to deliver process, productivity and performance improvements and build a competitive future through innovation.

2013 Results

Last year was one of the safest in our company’s history – the result of a disciplined safety management process that requires extensive collaboration, teamwork, and individual accountability for working safely each and every day.

The Carnegie Way is a strategic, disciplined approach to transforming United States Steel Corporation in meaningful, sustainable ways – from our processes and products to our culture, to the very work every employee performs and the value it creates for our many stakeholders, including our shareholders.

The death in December of one of our Great Lakes Works employees provides a sobering reminder that we must remain relentless in pursuit of our ultimate goal of zero incidents and injuries. Our journey to world-class safety performance serves as both an example and an inspiration as we undertake The Carnegie Way.

The disappointing business and financial results in the first three quarters of 2013 strengthened our resolve to move quickly, and we executed on a number of actions that are setting the stage for additional progress.

- In the spring, we began establishing the framework for The Carnegie Way, identified key due diligence teams across many of our core business processes, and began to mobilize with rigorous emphasis on Lean Six Sigma and project execution.

- In October, we announced a $1.8 billion goodwill impairment charge related to our 2007 acquisitions of Lone Star Technologies in the United States and Stelco Inc. in Canada.

- We completed negotiation of a successor labor agreement at U. S. Steel Canada’s Lake Erie Works. This new five-year agreement gives us an opportunity to pursue improvements that are important to the success of the facility as our company continues to make difficult decisions that will help us address the challenging environment that exists. One of those difficult decisions involved the permanent closure of the iron and steelmaking operations in Hamilton, Ontario.

- We permanently shut down two of our oldest and most capital-intensive coke batteries at Gary Works, and we agreed to dissolve our Double Eagle Steel Coating Company flat-rolled joint venture.

- We ended the year reporting positive adjusted earnings per share for the fourth quarter, the first quarterly profit since the third quarter of 2012.

- Our stock price improved nearly 65 percent from August 31 through December 31, 2013.

2014 – The Year

of Disciplined Execution

Although we are still in the early stages of our transformational process, we began 2014 having identified cost and margin improvements totaling $175 million annually, and we expect to realize $150 million of that figure this year.

Following a series of executive retirements last fall, several members of our executive leadership team transitioned into new roles that allow our company to capitalize on their extensive business and steel industry experience while giving them an opportunity to broaden their horizons. We also welcomed four new and talented business leaders to our company:

- David B. Burritt

Executive Vice President

Chief Financial Officer

- Suzanne Rich Folsom

General Counsel and

Senior Vice President

Governmental Affairs

- Charles G. Balawajder

Vice President

Chief Information Officer

- Christine S. Breves

Vice President

Chief Procurement Officer

Together, our entire executive management team represents a powerful combination of steel and industrial manufacturing experience, business transformation expertise, and the leadership capability to engage our employees to work differently, think big and drive change.

In January, we also announced additional steps we have taken or will be taking this year.

- We have filed for the necessary permits to construct a technologically advanced electric arc furnace (EAF) at Fairfield Works to replace the existing blast furnace-based steelmaking facilities. We see numerous advantages to adding EAF capabilities to our company’s operating footprint, in particular an increase in operational flexibility, and applying for permits is the next step as our analysis continues.

- We received the necessary state permits and approvals to extend our Minntac mine boundary and the permitted life of these mining operations as we continue to explore strategic opportunities that will generate additional value from one of our most significant assets and competitive strengths.

- Our U. S. Steel Canada subsidiary announced the difficult decision to reduce non-represented employment levels as part of our across-the-board, companywide program to reduce administrative costs.

- We plan to install a slab caster at our Granite City Works that we purchased from a now-idled former competitor to further increase the plant’s efficiency and capabilities.

Innovation Drives Improvements

We are exploring avenues that we believe will generate growth in products and markets that return the greatest value – both to our bottom line and to our customer relationships. In May 2013, we formally commissioned a state-of-the-art Continuous Annealing Line at our PRO-TEC Coating Company joint venture in Ohio. This line is capable of producing some of the most advanced cold-rolled, high-strength steels available in the world for use by the automotive industry in their efforts to lightweight their vehicles while also meeting increasingly stringent environmental and safety requirements. Our customers have responded positively, and we have already been awarded parts on several 2015 platforms across a wide spectrum of auto manufacturers. We expect this facility will play a role in ongoing efforts to develop and commercialize the next generation of advanced high-strength steels.

In 2013, U. S. Steel Tubular Products introduced another proprietary premium connection to the energy tubular marketplace – USS-PATRIOT EBM™ – and added a seal ring option to our USS-CDC HTQ™ semi-premium connection in response to customer feedback. We also increased the value-added services available to our tubular products customers through our Technical Sales team, Rig Site Services, and our expanded licensee repair network. Our research facilities worldwide are also accelerating their focus on product and solution development, which will be key in maintaining steel’s dominance as the material of choice in a variety of industrial and consumer product applications.

Our approach to innovation extends beyond the science of steelmaking. We are identifying new approaches to the manner in which we run our business, and we have chartered Lean Six Sigma projects within our core business processes to drive value-creating improvements.

High-Performing Organization

Our starting point for leading and managing The Carnegie Way is our company’s long-held commitment to operating in a highly principled and ethical manner. Cultivating a culture built on solid core values and ethical conduct is as critical to the current and future success of our company as it was to Andrew Carnegie’s ventures in the late 1800s. Our company’s values continue to serve as the foundation that guides our actions today, and we will not sacrifice our principles or ethics in pursuit of profitability. Our first chairman, Judge Elbert Gary, introduced his Gary Principles to our company and the business world in 1909, and we continue to live his belief “that when a thing is right, it will ultimately and permanently succeed.”

We are cautiously optimistic that we will have better economic circumstances in 2014, and we now have a performance scorecard and incentives in place to motivate behavior to generate more cash. Our investments in building organizational capability continue with a wide range of technical training programs that advance our unique steelmaking skills; our management development program for recent college graduates, many of whom will become leaders in the future; our leadership development programs, which emphasize our core competencies: delivering results, leading high-performing teams, leading change and customer service excellence; and our use of action learning as we embed Lean Six Sigma and project management into the DNA of our workforce and leadership team.

We recognize that we must adapt our business model to reflect certain new realities of today’s global steel industry – an industry that is dramatically different than just a few short years ago. The global economy still has not recovered to pre-recession levels of output, growth and employment. We face stiff competition within our own sector as well as from others seeking to replace steel as the material of choice in a variety of applications. In addition, imports of what we believe are unfairly traded steel products continue to flood markets worldwide, particularly the United States, which remains the most attractive and open market in the world. We continue to aggressively pursue trade remedies against unfair trade practices and filed a series of actions last year. On February 18, 2014, the United States Department of Commerce (DOC) issued a preliminary ruling with respect to its anti-dumping duty investigations of Oil Country Tubular Goods (OCTG) from nine countries. At this stage, the DOC found anti-dumping duties against eight of the countries involved in this case, but did not impose any duties on Korea – the largest importer of OCTG into the United States. We remain hopeful for a favorable final determination, which is scheduled to be announced in July 2014. Our Carnegie Way efforts are designed to enhance our competitiveness, but at the end of the day, we cannot compete against foreign governments with unfair, marketdistorting practices. The U.S. steel industry has only insisted on one thing – a level playing field created through the maintenance and enforcement of existing trade laws that make all trade truly free and fair. Let there be no doubt that our company’s vigilant efforts to defend and ensure enforcement of appropriate trade laws will continue.

In closing, I would like to recognize our recently retired Chairman and Chief Executive Officer John P. Surma, who served our company for more than 10 years, and four additional U. S. Steel executives who each served our company for more than 30 years: Gretchen Haggerty, Jim Garraux, Dave Lohr and Sharon Owen. We thank John, Gretchen, Jim, Dave and Sharon for their many contributions to our company and congratulate them on their many achievements throughout their careers.

United States Steel Corporation stands at an important and exciting point in our 113-year history, and I am truly honored to serve as your President and CEO. Through our focused, disciplined execution of The Carnegie Way, we are beginning to deliver results. On behalf of the executive management team, I would like to say:

To our employees around the world, thank you for working safely, ethically and smartly. Our organization is full of exceptionally talented and hardworking individuals who are fully engaged in efforts to think big and to think differently in order to create the kind of value we all know we are capable of delivering.

To our customers, thank you for your business. We will listen better, work harder and smarter, and do everything we can to help make you successful.

To our shareholders, we appreciate your continued support as we work to reshape, reposition and transform our company for a very competitive and sustainable future.

The transformational journey to return U. S. Steel to its status as the iconic American company has begun.

Sincerely,

Mario Longhi

President and Chief Executive Officer

John P. Surma

John P. Surma retired from United States Steel Corporation in December 2013 after 11 years of service to our company, including seven as chairman of the board of directors and 10 as chief executive officer. John was a highly respected and visible leader in the business world and championed the steel industry on every occasion. He made many contributions to our company during a career that included some of the most rewarding and challenging years in U. S. Steel’s history, but he took the most pride in serving as a vocal advocate for workplace safety. His personal, passionate belief that every U. S. Steel employee has the right to return home safely each day ignited our commitment to creating and sustaining one of the safest industrial workplaces in the world. Thanks to his unwavering leadership, our significant performance improvements have now positioned us as a global safety leader both inside and outside our industry. We thank John for the dedication, leadership and passion exhibited during his service to our company.